In this issue:

- sourcing disease-free seed

- sanitizing greenhouse spaces

- sterilize flats, cells, plugs, and other equipment

Sourcing disease-free seed

Seeds intended to be grown for transplant production should be certified ‘disease-free’. As per industry standard, most commercially bought seed comes with this certification and may be pretreated with a fungicide. Certification does not guarantee disease-free seeds; it means it has met the standards of the certification agency. Pythium spp. can cause damping-off to untreated seed during the early germination stage.

Hot water treatments are done to kill the majority of bacterial or fungal pathogens (not viral pathogens) that may be penetrated in the core of the seed. If treated incorrectly, pathogens will not be killed and reduce germination vigor or cause the seed to split.

Hot water treatment is typically done upon harvest and before storage. Only treat seed that will be used in the current season.

As an alternative to hot water seed treatment, use 1 part Alcide (sodium chlorite), 1-part lactic acid, and 18 parts water as seed soak. Treat seed 1-2 minutes and rinse for 5 minutes in running water at room temperature.

Hot Water Seed Treatment Instruction

- Place seeds to be treated in the porous containers, leaving enough room for the seeds to move around freely. Label each porous container with the seed type.

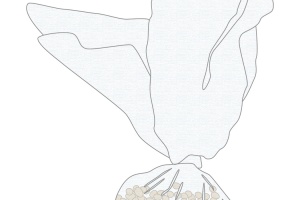

- Preheat the first bath/pot to 100°F. Once preheated, place the contained seeds in the first bath for 10 minutes.

- Preheat the second bath/pot to the recommended temperature for each specific crop. The temperature of the second bath/pot will range from 118-125°F and the treatment times will range from 20-60 minutes depending, on the crop. Place preheated seeds in the second water bath/pot and be sure to constantly hold the water at the recommended temperature. Ensure that treatment length and temperature are exactly as prescribed to avoid damaging the seeds.

- After treatment, place contained seeds in cold tap water for 5 minutes to stop heating action.

- Take the seeds out of the container and spread them in a uniform layer on a screen to dry.

- Plant seeds right away.

Additional Resources:

“Advantages of Using Certified Seeds” – Utah Pest Quarterly Winter 2016

“Saving Seeds Without Spreading Pathogens” – Utah Pests Quarterly Spring 2016

Greenhouse Disease Management / Transplant Production (Rutgers Vegetable IPM)

Sanitizing greenhouse spaces

Greenhouse sanitation is critical for disease-free vegetable transplant production. It is an expectation from consumers that the product they are purchasing will grow with vigor and have low initial risk of disease or pests.

- Remove any weeds growing inside or around the greenhouse structure before any production begins.

- All transplants brought into the greenhouse from other locations should be inspected for any possible insect or disease problem. Do not expose your space to problem plants.

- Sweep floors and sterilize all the benches within your greenhouse.

Additional Resources:

Cleaning and Disinfecting the Greenhouse (Massachusetts Extension)

Guide to greenhouse sanitation for growers (Michigan State Extension)

Sanitation for Disease and Pest Management (Purdue Extension)

Sterilize flats, cells, plugs, and other equipment

Emerge flats, plugs, cells, and other growing containers in a chlorine sanitizer solution (3.5 fl oz. of a 5.25% sodium hypochlorite equivalent product per gal of water) for about 20 minutes. Wash flats and trays with clean water or a Q-salts solution to eliminate the chlorine.

Production Recommendations:

- Quaternary ammonium chloride salts

These products are labeled to control fungi, bacteria, viruses, and algae. They may be applied to benches, growing contains, floors, and walls.

e.g. Green-Shield®, Physan 20®, and KleenGrow® - Hydrogen Dioxide, Hydrogen Peroxide, and Peroxyacetic Acid containing products

These products are labeled to control bacteria, fungi, and algae. They may be applied to benches growing containers, and other equipment.

e.g. ZeroTol® 2.0, OxiDate® 2.0, and SaniDate®12.0 - Chlorine bleach

Chlorine bleach products are best only used in growing containers and not greenhouse surfaces (walls, floors, and benches). When used properly, chlorine is an effective disinfectant. A water + chlorine bleach solution is short-lived and should be used immediately.

e.g. Clorox®